- STEMCO recommends a complete wheel end inspection following an incident with water submersion.

- If wheel ends are not properly repaired, wheel end performance may degrade and cause possible failure.

- Caution should be taken to protect technicians and the environment from units that have been submerged in water.

LONGVIEW, Texas - STEMCO, an EnPro Industries company (NYSE: NPO) and leading manufacturer of heavy-duty components and solutions for commercial vehicles, is recommending a complete wheel end inspection for tractors and trailers that have been exposed to flood waters as a result of hurricanes Harvey and Irma.

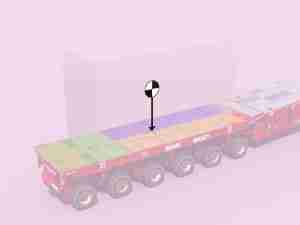

In light of the recent weather events and severe weather involving flooding and storm surge, STEMCO is offering detailed instructions on how to complete a wheel end inspection and/or repair to ensure performance is optimal and catastrophic wheel end failure is avoided.

“Water, especially salt water, is one of the most corrosive contaminants that can seep into the wheel end and affect the functionality of the bearings, both short- and long-term,” said Chip Stuhr, director of STEMCO Wheel End products. “To avoid wheel end failure, costly maintenance and potential safety risks on the road, it’s critically important not to put any unit into service until it has had a complete wheel end inspection or repair.”

To access the STEMCO Tech Tip detailing how to identify wheel end type and conditions that may degrade lubricant and metal components, including STEMCO Sentinel® Hub Caps and non-Sentinel® hub caps, click here: “

Inspection, Rebuild, Reassembly of Submerged Tractor and Trailer Wheel Ends.”