Page 1: Port 1.0

Page 2: Port 4.0

Page 3: Terminal Complex…ities

On the simplest level an ocean container is nothing more than a six-sided rectangular metal box. But a container terminal’s role in expediting the movement of those boxes and pushing them through a complex, increasingly digital, supply chain may inspire another container revolution – Port 4.0

Container terminals, and indeed the entire box business, are experiencing a great identity crisis. That’s not surprising as the box terminal business is entering its seventh decade, a mature industry by any measure. Still this is an existential moment for the industry as it probes its way forward into a digital age, wrestling with the most basic of issues – how to move a six-sided rectangular metal box more efficiently. And “efficiently” is increasingly being measured holistically from the factory floor to the customer’s door. This concept isn’t new but calls into question the future role of container terminals within the 21st century supply chain. Arguably, with the exception of the containership itself, the container terminal asset has the greatest impact on the “success” of the containerized supply chain. But as terminal automation moves closer to terminal digitalization, what role will the container terminal play in the supply chain a decade or two or three from now? Will the terminal even be recognizable?

But to look forward, it is necessary to take a quick look back at the basic underpinnings of container terminal development.

Port 1.0

Before Malcom McLean’s Ideal X made the first voyage of a containership between Port Newark, New Jersey and Houston, Texas on April 26th, 1956, shipping was just shipping. Just as Henry Ford didn’t invent the automobile, neither did McLean invent unitized shipping but by separating the box from the chassis and loading just the container for ocean transit, an economic transformation occurred. Numerous steps in handling were eliminated and efficiencies were gained through the emergence of an embryonic “supply chain” linking manufacturer to customer. In August of 1962 the Port Authority of New York-New Jersey (PANYNJ) opened the world’s first container terminal – Elizabeth Marine Terminal in New Jersey – and the container revolution was underway.

How effective was this new box system? In 1965 waterfront labor loaded around 1.7 tons per hour. By 1970 with the advent of gantry cranes and box terminals that number moved to 30 tons per hour. The impact of these economics on ocean freight was enormous as container volumes rose from 1.7 million TEUs in 1970 to 27.6 million TEUs twenty years later (1990). The impact of the box on ocean carriage was astounding. For example, in terms of tons carried per dwt tankers, they held a significant edge over containerships and dry bulk carriers for decades. But by 1980 containerships slipped ahead of tankers and since then have vastly out performed all other vessel types on per ton basis.

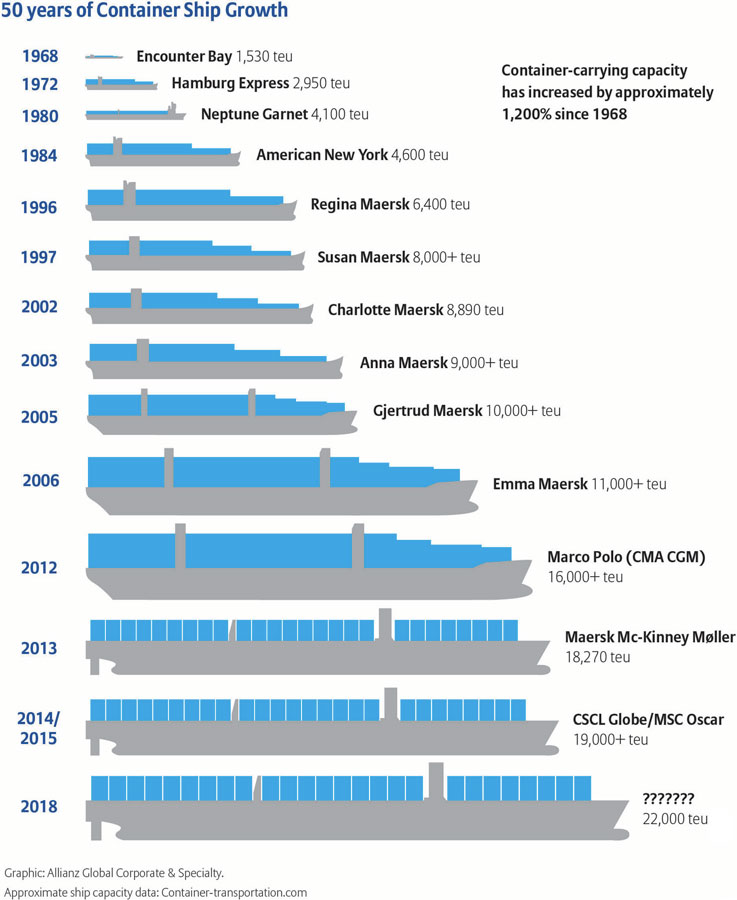

Of course, the growth in boxships both in size and numbers and increases in the volumes of containerized freight fed a global four-decade growth spurt in container terminal construction. But this growth wasn’t without significant and on-going challenges. Bigger ships, demanded larger handling equipment, deeper channels (AAPA has noted, an on-going issue for U.S. ports) and an insatiable need for more space to store containers. The supporting infrastructure outside the gates also has had to follow suit to accommodate the flow of ocean containers moving inland. Finally, the entire process has now had to be automated and digitalized to enable sufficient freight velocity throughout the supply chain. And the mandates of abutting communities, coupled with rising environmental concerns underscores the multi-level complexity involved on overhauling container terminal operations.