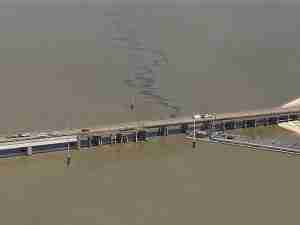

Hutchison Ports Port of Felixstowe has reached a significant milestone by becoming the largest UK port to deploy 5G technology and the Internet of Things (IoT).

The Port of Felixstowe along with consortium members, Three UK, Blue Mesh Solutions and the University of Cambridge was successful in an application for grant funding under the 5G Testbeds and Trials program run by the Department for Digital, Culture, Media and Sport (DCMS). The project aims to prove 5G’s capabilities in a busy port environment.

The project seeks to deliver on two use cases: predictive maintenance of quay cranes using Internet of Things (IoT) sensors and providing communications for remote control yard cranes.

Digital Infrastructure Minister Julia Lopez said: “It’s incredible to see our £200 million investment in innovative 5G tech is empowering Britain’s biggest and busiest container port to explore new ways of driving efficiency, improving safety and supporting the UK’s post-Brexit status as a global trading nation.

“5G has huge potential to revolutionize a wide range of UK industries and 5G Ports is just one testbed the government is funding to help achieve this.”

Karen Poulter, Head of Information Services, Port of Felixstowe, and 5G Project Lead, commented: “As part of the 5G project, six quay cranes are being fitted with IoT Sensors to understand the stresses and strains placed on them by day-to-day operation. Using 5G to transmit the data enables these systems to operate in real-time which could enable ‘in the moment’ safety-critical applications.

“Using the data generated by the IoT sensors and linking it to the actual activity on the crane together with previous maintenance records, Cambridge University is developing an algorithm to predict equipment failure and suggest the optimum time to maintain the equipment.”

The availability of equipment is integral to port operations. Routine maintenance is an absolute necessity but can restrict equipment availability. The algorithm will maximise the amount of time cranes are in use and will reduce the cost associated with emergency repairs and day-to-day maintenance.

The 5G network can handle the huge volume of data collected which will be used to train the algorithm at levels that wouldn’t be sustainable over 4G.

Prof Ajith Parlikad, Professor of Asset Management at the University of Cambridge, commented: “We will harness the speed, low-latency and high-capacity of 5G to send the high volumes of data generated by the IoT sensors for an Artificial Intelligence based predictive maintenance system. This system will be able to detect anomalies in the cranes and alert the operators so that preventive maintenance can be targeted at these areas before the failure actually happens.”