ABB collaboration with Ballard advances fuel cell ships

Electronics maker, ABB, and Ballard Power Systems, a maker of fuel cell technology have signed a Memorandum of Understanding (MoU) to develop the next-generation zero emission/ fuel cell power system for ships.

The two companies propose to develop an electrical generating capacity of 3MW (4,000 horsepower) module “no bigger in size than a traditional marine engine running on fossil fuels,” according to a June 27th news release.

ABB (ASEA Brown Boveri) is a Swedish-Swiss company headquartered in Zurich, Switzerland that produces electronics, robotics, heavy electrical equipment and automation technology.

At the Electric and Hybrid Marine Expo in Amsterdam on June 27th, Dr. Sami Kanerva, senior principal engineer, ABB, told conference participants that fuel cell technology provides a long-term solution for the maritime industry to replace fossil fuels.

In his presentation summary Kanerva noted “Fuel cells enable zero-emission operation, lower maintenance cost and higher efficiency than a combustion engine. The technology also allows energy to be concentrated more densely than in petroleum fuels.”

“The next generation of ships – electric, digital and connected – will require energy sources that are not only able to meet the increasing demands for fuel efficiency, but will also enable cleaner and safer shipping,” said Peter Terwiesch, president ABB's Industrial Automation division. “We are excited to collaborate with Ballard Power Systems on driving the development of the next-generation fuel cell technology that will power the vessels of the future.”

“This MoU is a significant next step in our ongoing relationship with ABB, the innovative market leader in marine solutions,” said Rob Campbell, chief commercial officer at Ballard Power Systems. “The rapidly evolving marine market represents an exciting growth opportunity for zero-emission fuel cell technology. And, Ballard’s prior development and deployment of megawatt-scale containerized … fuel cell systems for land-based use gives us the critical experience and knowledge to collaborate effectively on the development of clean energy solutions for key marine market applications.”

The two companies noted that fuel cell systems can have various applications for vessels, such as providing power for a ship’s hotel operations during the time of docking, or for powering the propulsion when ships are at sea. During the initial phase, the collaboration will focus on the development of fuel cell power systems for passenger vessels.

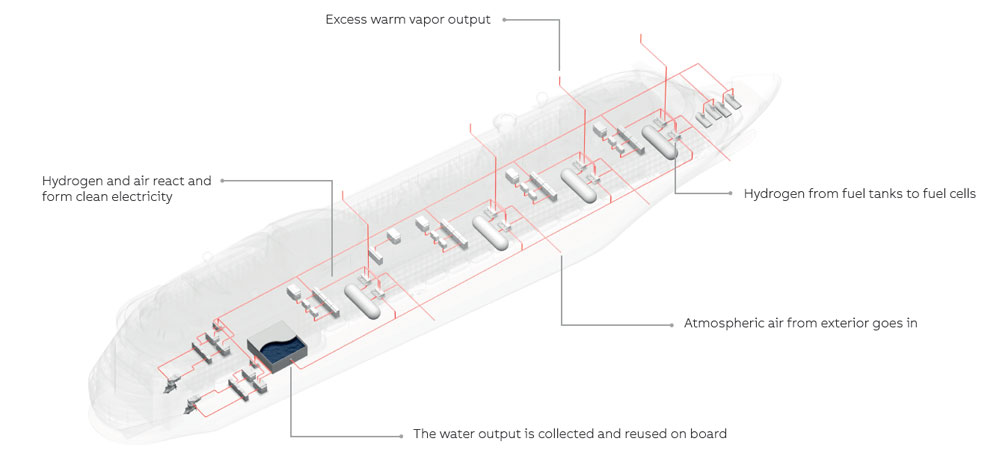

The proton exchange membrane fuel cells (PEM) convert the chemical energy from hydrogen into electricity through an electrochemical reaction. They involve no combustion, converting fuel directly to electricity, heat and clean water. With the use of renewables to produce the hydrogen, the entire energy chain can be clean, as seen in the following example:

- In 2017, ABB announced that it was deliveringitsfirst fuel cell system for Royal Caribbean. The system will be deployed on board a Royal Caribbean vessel and will be the first fuel cell system to provide an energy source for a luxury cruise ship. “Our goal is to take the smoke out of the smokestacks, said Harri Kulovaara, executive vice president of Maritime and Newbuilding, Royal Caribbean Cruises Ltd. “We are dedicated to innovation, continuous improvement, and environmental responsibility, and using fuel cell technology gives us the opportunity to deliver against all three of these pillars.”

- ABB is also participating in the Maranda research vessel fuel cell project, where a mobile hydrogen storage container will be developed, improving access to hydrogen for marine applications. “Maranda will be operative next year, with others following closely, both newbuild and retrofit projects. There are four or five commercial marine projects underway right now, with three in Norway alone,” an ABB executive noted.

“Fuel cells have been the next big thing for 25 years,” says Jostein Bogen, product manager in ABB Marine & Ports noted in an ABB background paper: “Now it’s really happening.”

“There is a lot of movement in the market, and various technologies are being developed in parallel,” says Bogen. “We believe the Proton Exchange Membrane, or PEM technology shows the most promise, and is the most sustainable.”

There has already been considerable utilization of fuel cells in trucks and buses, he noted. Hydrogen trucks and busses are already on the roads, and Bogen notes that one fuel cell manufacturer claims it will install the same capacity in fuel cells in the next two years as they did for the last 20 years.

Deliveries for trains are expected to follow soon, and Royal Caribbean Cruise Lines has announced plans to work with the Meyer Turku shipbuilding company in Finland on fuel cell use in its new LNG-powered cruise ships, with testing already underway.

ABB executives told AJOTthat the costs of hydrogen fuel and fuel cell marine power systems are still too high to attract most shipowners. They note, however, that the cruise ship industry is a good starting point, because: 1) the industry orders a lot of ships and ship engines and 2) the industry is looking to lower its emission footprint and find long-term alternatives to diesel fuel and diesel fuel emissions.

Bogen stated that the marine industry has also learned a lot from the development of LNG as fuel. “Just as the big shipowners went in for LNG and the infrastructure eventually followed, the same could happen with fuel cells and hydrogen.”

The EU, Japan, the US and now China are all moving on hydrogen fuel cell technologies and promoting their use in various applications: “For ABB, the future is electric power. In this scenario, the ideal ship would be hydrogen electric. This would allow us to move away from combustion in 20-30 years, probably with a combination of batteries and fuel cells.”

© Copyright 1999–2024 American Journal of Transportation. All Rights Reserved