Climate technology startup Twelve took a major step towards producing sustainable aviation fuel (SAF) on Thursday by launching its commercial-scale carbon transformation unit.

The company will generate carbon credits for customers including Microsoft Corp. and Shopify Inc., in addition to producing clean jet fuel for Alaska Air Group Inc. Twelve is one of a number of emerging companies working on ways to transform captured CO2 into useful products. In the case of the Berkeley, California-based startup, its nascent technology will be critical to cleaning up one of the hardest-to-decarbonize sectors: aviation.

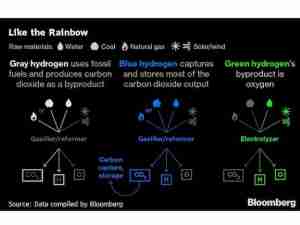

Twelve uses a technique called electrolysis that uses electricity to repurpose carbon dioxide and water into various products. When the electricity is generated from renewables, the process is essentially no-carbon. The company’s CO2 electrochemical reactor — called OPUS — will be at the center of its first commercial SAF production plant under construction in Moses Lake, Washington, that’s set to be completed later this year. The plant will run on hydropower and use CO2 captured from a nearby ethanol plant. That CO2 and water will be fed through OPUS and turned into synthetic gas, the basis of SAF. Twelve’s airline customers can blend it with traditional jet fuel. The resulting carbon credit can be bought by corporate customers like Microsoft to offset their business travel-related emissions.

The system is about the size of a shipping container, and Twelve’s electrochemical reactor technology allows it to produce fuel without taking up much space, Twelve co-founder and Chief Science Officer Etosha Cave said. Its unique low-temperature environment also allows the reactor to be ramped up and down fairly quickly, which means it can run when renewable prices are at their lowest compared to higher-temperature units that must run 24/7. The low temperatures also make for lower capital expenditure costs, according to CEO Nicholas Flanders.

CO2 electrolysis isn’t widely used today, though a study published last year in Joule found the technology is maturing and that it will be a “critical step” to cutting CO2 emissions for the fuel and chemical industries. SAF is also a long way from being cost competitive with traditional jet fuel, but airlines are under increasing pressure from governments and their own net zero commitments to integrate SAF into their fuel mix. The European Union has mandated that regional SAF usage needs to reach 2% by 2025, with the percentage rising to 70% by 2050. As of 2022, SAF accounted for 0.1% of the world’s jet-fuel supply, according to BloombergNEF.

Incentives like those within the Inflation Reduction Act (IRA) signed by US President Joe Biden are also spurring the development of technologies to create SAF. Although Twelve’s carbon transformation technology can be used to make products ranging from spandex pants to car parts, it pivoted to focus more fully on SAF after the announcement of IRA tax credits for SAF blending, carbon capture and utilization and hydrogen production, Twelve Cave said. Those tax credits helped the company launch this commercial unit.

“Without that, we would not be competitive in terms of being able to get to market at the stage we’re at,” she said.

Twelve would not disclose its current cost to make the fuel, though it said it expects prices to go down as its technology scales up and eventually reach parity with traditional jet fuel.

Currently, most SAF is made from animal fats and waste cooking oil or plants and wood. Biomass-based SAF has been around for years at commercial scale, though it still represents an exceedingly small portion of all jet fuel used.

Fuels made from captured CO2 — dubbed “synthetic fuel” — like Twelve’s are far from commercialization. It’s likely that there will be a role for both types of SAF, as the former could be limited by land and feedstock availability and the latter by the availability of clean energy. Both are “drop-in” fuels that can be subbed in for fossil-based fuels and don’t require costly new engines, which is what makes them appealing to an industry with expensive and hard-to-replace assets like airplanes.

Almost 40 major airlines have made net-zero emissions commitments, according to data from BNEF. But there’s unlikely to be enough SAF supply to meet these commitments. While smaller planes and some short-haul flights could be decarbonized via electric and hydrogen-powered planes, most mid -to long-range flights will have to depend on SAF.

Overall, the supply of SAF is likely to be 30% to 40% below the industry’s demand by the end of the decade, according to Cathay Pacific’s head of procurement operations and development Kristof Van Passel. “And we expect that gap to widen,” he said at a BloombergNEF conference in January.