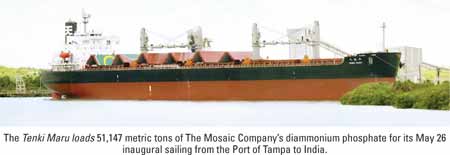

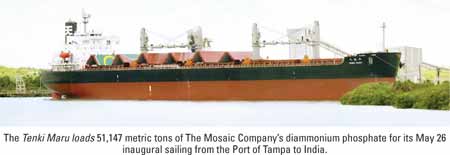

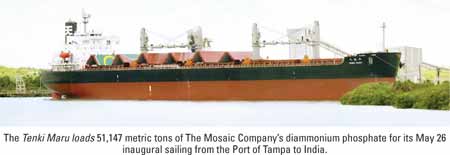

The Mosaic Company assembles supply chain to help feed people worldwide

By Paul Scott Abbott, AJOT

Just as an artistic mosaic is an arrangement of small pieces of stone into a work of art, the multifaceted supply chain of The Mosaic Company is an assemblage of routings of cargos – including small pieces of stone – that constantly sees vessels traversing the Gulf of Mexico.

Unlike artists, however, whose goal is to create a work on which to feast the eyes, the mission of the people at Mosaic is a higher one – to feed the world.

Whether exporting millions of tons of finished fertilizer from Tampa, moving phosphate “rock” to Louisiana and returning with coal on the cross-Gulf backhaul, or transporting cargos on any of several other supply chain routes, Plymouth, Minn.-based Mosaic is clearly a major player in the Gulf shipping scene.

Mosaic’s multiple transportation demands keep Doug Montgomery, the company’s assistant vice president of supply chain, a busy man as he and the company’s supply chain group direct the movements of some 50 million tons of products a year.

“It’s never a dull moment,” said Montgomery, citing the numerous distinct cargos and routings, as well as challenges in dealing with seasonal demands for fertilizer products.

“Our job – to try to make the supply chain as efficient as possible – we see as very important,” said Montgomery, whose office is just outside Tampa, in Riverview, Fla. “It involves a fine balancing act between cutting costs and making sure our service to customers is as good as it can be.”