Autocar, LLC celebrates the brand’s innovation history with its American-made trucks that are Always Up.

North America’s oldest truck brand is commemorated for representing 125 years of custom engineering and innovation in the vocational trucking industry. Autocar, LLC, manufacturer of premium, severe-duty, custom-engineered vocational trucks, recognizes the impact the Autocar brand has had throughout North America and is grateful for the tremendous support of the company’s longstanding customers. Since the brand’s creation in 1897, trucks carrying the Autocar name have been custom engineered to unique customer specifications. This ethos remains the core of the brand today: a direct relationship with customers to exceed their expectations.

Autocar, LLC, the 100% American-owned company, assembles all of its trucks in the United States and is headquartered in Birmingham, Alabama with an additional manufacturing location in Hagerstown, Indiana. The vocational trucks coming out of Autocar’s facilities support America’s economic infrastructure by providing critical tools for waste collection, transportation and logistics, construction and concrete sectors. Importantly, the company is not set up by vehicle platform but by vocation, making its obsessive customer drive to solve specific vocational jobs possible.

“For well over a century, the Autocar brand has exemplified innovative designs, agile custom engineering and purpose-built severe duty trucks that continue to shape the American vocational truck industry,” said Andrew Taitz, chairman of Autocar, LLC. “Since the brand’s humble beginnings in 1897, Autocar trucks have been automotive pioneers ahead of their time. In 1899, the Autocar name was introduced on the first commercially available motor truck in the United States and even marked America’s first electric truck in 1923. Today, we celebrate the Autocar brand embodying 125 years of customer excellence and the formidable reputation it symbolizes. We value our customers, staff and communities for their unwavering commitment and support as we look forward to a bright future of doing what we do best - building BADASS vocational trucks that keep America moving forward.”

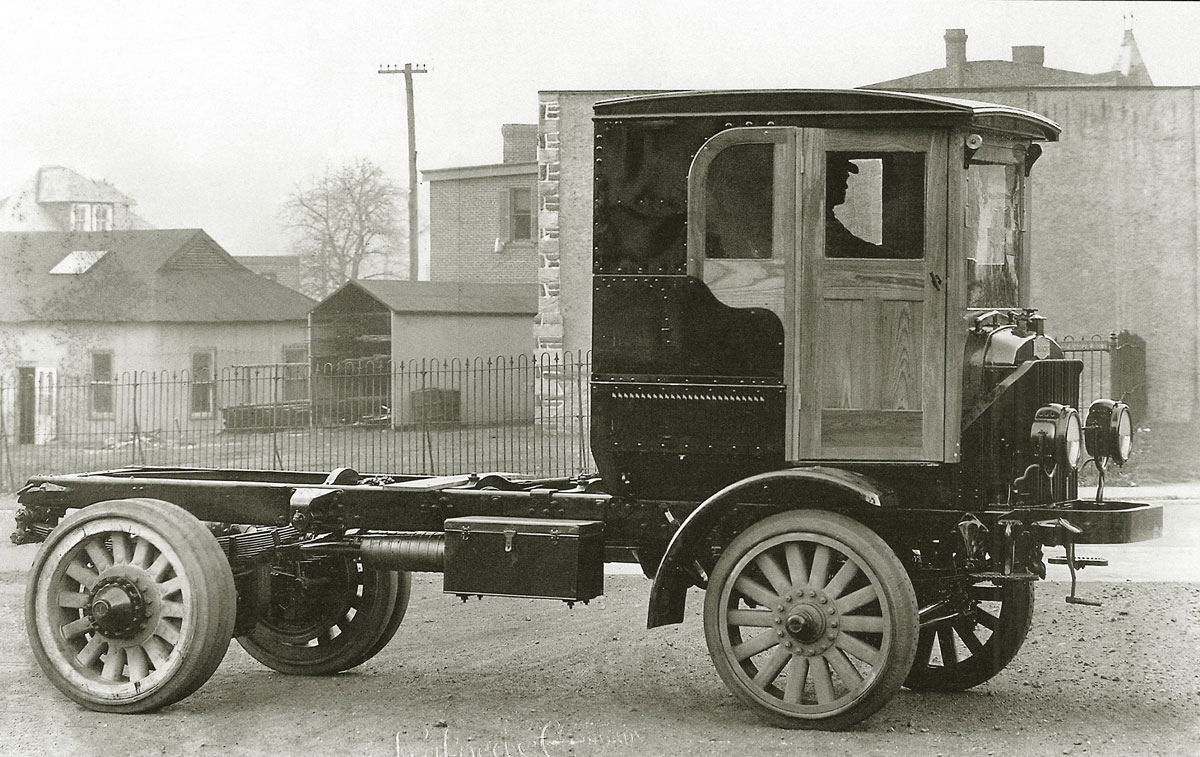

Exactly 125 years ago, Louis Semple Clark introduced the world to the “Autocar No. 1,” an automobile that forever changed the American automotive industry. A few years later, that early company evolved into producing tools for the vocational truck industry with the introduction of the double-rear reduction axle, an engineering innovation still used by today’s Autocar for select applications.

A legacy of fleet electrification. Trucks bearing the Autocar badge ushered the industry into the era of electrical vehicles almost 100 years ago, demonstrating the forward-thinking mindset that still shapes the brand today. Starting in the 1920s, the first vocational trucks carrying the Autocar name offered electric vehicle options for commercial use after the need for modernization and leaner business operations was recognized. These trucks were common throughout the 1920s and 1930s with Autocar’s E1, E3 and E5 models found throughout America’s city streets.

Now, almost 100 years later, Autocar, LLC remains an industry leader in green innovation, reintroducing all-electric zero-emission vocational vehicles such as the E-ACTT and the E-ACX. The E-ACTT all-electric terminal tractor has a duty cycle of up to 22 hours per charge with significantly lower maintenance and increased productivity. The recently-announced E-ACX, a severe-duty refuse collection cabover, is the only vocational truck with a universal battery and a proprietary electric powertrain system specifically designed for severe-duty vehicles. As more fleets look to electric options for sustainability, the same benefits of reliability and cost-savings discovered over a century ago continue to resonate with fleets today.

Autocar is a totally different OEM. Autocar, LLC is the premier manufacturer of custom-engineered vocational trucks for refuse, recycling, logistics, construction, concrete, and road maintenance. Autocar stands behind its products and its Always Up promise by doing things completely differently to the rest of the market. They do not design proprietary parts into their trucks, they offer warranties on nonproprietary parts, set their business up to work directly with the customer on design and offer 24/7 support from factory-trained technicians for the life of the truck…which is a very long time!

Trucks are custom engineered for each customer application. The iconic Autocar bowtie logo symbolizes a timeless commitment to customer obsession: staying true to everything that makes the Autocar brand the gold standard for customer-focused, purpose-built severe-duty vocational trucks. Every truck built by Autocar is customer-specific and custom-engineered for the unique demands of the customer’s application.

In 2021, Autocar, LLC ushered in the future of the brand’s conventional truck model with the introduction of the DC-64 truck series, a model configured to support refuse and construction applications such as roll-offs, dump trucks, mixers and concrete pumps. The DC-64 has a galvannealed steel cab, best-in-class driver visibility, 160k PSI chassis and partners with body companies to deliver the highest level of body integration in the industry. Autocar’s team leveraged over 120 years of historic Autocar designs to create a truck that pays homage to earlier features of Autocar-brand trucks such as the iconic Autocar split grille and round headlights. In addition to the conventional cab designs, Autocar, LLC manufactures two cabover models, the ACMD and ACX, as well as the ACTT terminal tractor and E-ACTT all-electric terminal tractor.

A focus on industry-leading body integration. Autocar knows that maximum uptime is a top priority for fleets and operators, which is why all Autocar trucks are engineered to their specific application and body. With industry-leading body integration options, Autocar team members learn the needs of their customers’ businesses first and then build a complete tool to exceed customer expectations.

Autocar is the only OEM that offers the Power of One, a body integration process that enables engineers to work with body companies for parallel engineering of the truck to a specific body. Through partnerships with select body companies, Autocar can install body components during the production process such as electrical harnesses and bolted components, drastically reducing the need for welding, stripping, drilling and significant alterations during body installation. The newly introduced DC-64R severe-duty conventional truck epitomizes the brand's innovation track record achieving a new breakthrough in chassis-body integration. Autocar takes responsibility for building this truck as one complete tool and mounts the roll-off hoist body directly on the Autocar DC truck production line for superior up time and performance.

Highlights and Firsts of the Autocar Brand:

1897 – The “Autocar No. 1” was built by Louis Semple Clark

1899 – The Autocar brand designates the first motor truck commercially available in the United States. This truck was “purpose-built” for their customers’ need to carry and deliver packages

1907 – Autocar-brand trucks incorporated focused engineering from the early days of the motor vehicle industry, including many breakthrough inventions that have become standard in today’s trucks and cars:

- The first left-side drive vehicle, when center-drive was common

- The first American shaft-driven vehicle, replacing chain-drive

- The first double reduction rear axle, for smoother power transmission

- The first American porcelain-insulated spark plug

- The first circulating oil system

1911 – The Autocar brand began exclusive manufacturing applications for trucks

1910 –First Autocar-brand electric trucks introduced

Today’s Innovations From Autocar, LLC:

2008 – Autocar, LLC introduced the ACX, a cabover featuring many industry firsts like a spacious and ergonomic cab design, industry-best visibility, and integrated body controls

2008- Autocar began offering compressed natural gas integration of (CNG) trucks, years before its competitors. Autocar remains the leader for CNG Refuse trucks today.

2017 – Autocar was the first OEM to offer fuel-saving technology to help lower emissions

2018 – Autocar introduced Power of One® the most advanced body integration for refuse trucks

2019 – Autocar announced its DC-64 series with a lineup of severe-duty conventional trucks with the DC-64R refuse truck, DC-64M concrete mixer, and DC-64P concrete pump truck

2021 – The nation’s first BADASS™ dump truck, the DC-64D, was introduced, joining Autocar’s DC-64 series

2021 – Autocar became the first OEM to offer an Advanced Driver Assist System (ADAS) for cabover refuse trucks

2021 – Autocar announced its zero-emissions all-electric terminal tractor, the E-ACTT

2022 – Autocar introduced the E-ACX, its zero-emissions and zero-compromise all-electric refuse truck, built to use any battery the customer decides for their programming.

_-_28de80_-_9b2f972cdce64d5f7c8d952d74a16521db70a589_yes.jpg)