• “Retailers must get used to keeping higher inventories as Supply Chain disruptions become a norm” said Christian Roeloffs, cofounder & CEO, Container xChange

• Notable rise in demand for containers in China and South Asia as well as in Container trading spot rates ahead of the Chinese New Year

• Average rate on China-Europe quoted this week is about US$5400/40’HC, up from US$1,500 just the week before

• Container Price Sentiment Index (xCPSI) reaches an all-time high in anticipation of container price rise owing to the Red Sea crisis

The Red Sea, a vital conduit for East-West trade, is undergoing unprecedented turmoil due to persistent attacks by Houthi rebels, causing significant uptick in fuel and insurance costs, longer voyages and capacity soak up for the transportation and logistics sector.

Container xChange, an online container logistics platform for container trading and container leasing, issues a critical advisory as the Red Sea crisis deepens, impacting the landscape of global maritime trade.

Recent attacks by Houthi rebels have persisted on the Red Sea, with the most substantial assault launched on January 9, 2024, indicating a continued threat to maritime traffic in the Red Sea.

Customers of the Container xChange platform affirm that the shipping lines have raised their slot prices significantly. A Container xChange customer based and operating in Singapore shared on the Red Sea matter that, “Average rate on China-Europe quoted this week is about US$5400/40’HC, up from US$1,500 (3X) just the week before.”

Container trading spot rates shoot up by 48% in Latin America East in the last 30 days (as on 11 January 2024)

Latin America (East and West), Japan & Korea and Europe Mediterranean witness highest increase in Container trading spot rates over the last 30 days.

“We foresee that the rate hikes will flatten out in the mid to long term. We have enough capacity which can be soaked up in longer transit times and yet not cause permanent capacity crunch.” said Roeloffs.

Demand for Containers shoot up

There is a growing demand for containers in Asia as shippers and forwarders foresee cargo demand in the coming weeks, to fulfil orders ahead of the Chinese New Year. A container manufacturer from China shared with Container xChange, “Shipping companies are demanding more containers now as they avoid red sea. Therefore, Shipping companies and leasing companies have placed more than 750,000 TEU ISO container orders out of China in the last two months.”

Meanwhile, container trading spot rates are increasing at a staggering rate as observed on the Container xChange platform. Spot rates in Shanghai, Hamburg, Boston, in the illustrations below, indicate examples of the steep demand increase that is currently being witnessed for boxes in these hotspots.

As an immediate reaction to the disruption, these average container spot rates and prices are expected to rise, but then plateau after reaching a high.

The container price sentiment Index (xCPSI), a sentiment tool by Container xChange to measure market sentiment for container price development, reached an all-time high as container price anticipation peaks. This indicates that the supply chain professionals are expecting these prices to further shoot up in the coming weeks significantly.

The index value peaked at 71 in January from an average of 27 in December, mirroring the significant impact Red Sea attacks have had on prices so far.

The Ultimate Cost Burden

The two visible and obvious cost components that are leading to higher transport costs resulting from rerouting to Cape of Good hope are – insurance and fuel costs.

Insurance for cargo transiting Red Sea has become challenging. On top of it, insurance costs have surged in anticipation of the difficulties and challenges that do not seem to taper off.

Another element is the fuel cost which has increased roughly by 20-23% by way of traveling through the Cape of Good Hope, as compared to the traditional Suez Canal route.

“Ultimately, the final consumer pays the freight cost. In the short term, usually there is some intermediary that pays the bills, because they have promised at some certain price, but ultimately in normal circumstances, the price per unit is adjusted marginally to the end consumer when such a disruption occurs.” added Roeloffs.

Fine-tuning Inventory management strategies

“There is always safety stock, that retailers keep, so buffer stock is there. Yes, it soaks up some capacity, but this event doesn't have the capacity to impact inventory to an extent that we do not see products on the shelves. I don't see that coming.” added Roeloffs.

The shipping and the global trade largely have become relatively more resilient to supply chain shocks as these become evidently more frequent and persistent.

“As we witness continued disruptions disturbing the global supply chains in the mid to long term, we will see enhanced supply chain resilience.” added Roeloffs.

The bulk, oil and gas sector have no impact so far whatsoever as the vessels carrying these continue to operate on the Red Sea. There has been no attack on these vessel types. High value container vessels are being diverted, impacting the big east-west trade from Europe to Asia and vice versa.

So far, Out of 700, some 500 vessels have been diverted soaking up significant capacity from the existing overcapacity that the industry was grappling with.

As businesses face this new challenge, there are three immediate recommendations that can improve the situation handling currently for companies-

- Hold Adequate Safety Stocks: Maintaining sufficient safety stocks is crucial for absorbing disruptions without significantly impacting inventory levels.

- Enhance Flexibility: Operating with multiple networks and suppliers adds resilience, reducing dependency on a single source.

- Leverage Technology: Embracing technology is paramount for identifying problems in (or almost) real-time and making informed decisions, ensuring a proactive response to disruptions.

Note of context:

In a troubling turn of events, the Red Sea, a vital artery for global maritime trade, is facing unprecedented disruptions, primarily due to recent attacks by Houthi rebels on ships passing through the region. The Red Sea, with its strategic importance accentuated by the Suez Canal, serves as a crucial superhighway connecting Europe, Asia, and Africa. Recent attacks have escalated operational costs, creating significant challenges for shipping industries and placing downward pressure on profits. The Bab el Mandeb strait, also known as the Gate of Grief, has become a focal point, and its geographical challenges make it a critical chokepoint for maritime traffic. The disruption is not only impacting the flow of goods but also leading to a substantial re-routing of vessels, resulting in increased shipping costs, longer voyages, and environmental concerns.

Impact Highlights:

- Rerouting Challenges: Vessels are diverting around the Cape of Good Hope, leading to increased fuel costs, environmental concerns, and impacts on shipping efficiency.

- Shipping Industry Strain: Shipping costs have surged, with a 60 percent drop in vessels passing through the Suez Canal.

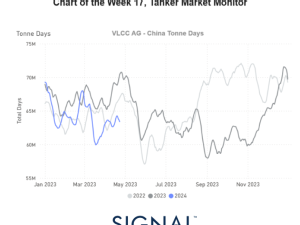

- Oil Tanker Stability: Despite disruptions, oil and fuel tanker traffic in the Red Sea remained stable in December, providing a glimmer of hope for stable energy supply chains.

- Rising Shipping Costs: The Red Sea crisis is projected to push shipping costs up to 60 percent, coupled with a 20 percent increase in insurance premiums, affecting overall operating costs.

- Insurance Challenges: War risk premiums for shipping have surged, impacting transportation costs and potentially leading vessels to seek alternative routes.

- Re-routing Impact: Re-routing through the Cape of Good Hope results in 10-20 days of delays, adding complexity to logistics and affecting delivery timelines.

- Supply Chain Disruptions: The Red Sea crisis spotlights broader issues of supply chain disruptions, requiring strategic planning and forecasting by companies to navigate challenges.

As the Red Sea crisis unfolds, the global shipping industry faces unprecedented challenges, necessitating collaborative efforts and strategic solutions to ensure the resilience of supply chains and mitigate the far-reaching impacts on international trade.