Shipping Technology

Speed to Quote™ is turbocharged with certified DAT integration

| January 20, 2022 | Shipping Technology

New Avetta One™ platform provides unified view of supply chain risk for companies and their suppliers

| January 19, 2022 | Shipping Technology

Leaders in packaging equipment, PAC machinery, enters new top fulfillment auto bagger for an MHI, MODEX show innovation award

| January 19, 2022 | Shipping Technology

PAC Machinery, Leaders in packaging with one of the most diverse ranges of machinery, has entered the Rollbag® R3200 Fulfillment Automatic Bagger in the MHI Innovation Award competition in the “Best New Innovation” category. Winners will be selected at the 2022 MODEX show in Atlanta, GA at the World Congress Center held March 28-31, 2022. The R3200 Fulfillment Bagger was also just named one of PAC's top selling machines of 2021.

CHAMP’s MarketAnalytics launch set to transform air cargo insights

| January 19, 2022 | Air Cargo | Technology | Shipping Technology

TransImpact acquires forecasting and demand planning software company

| January 18, 2022 | Shipping Technology

AIN and xChange announce new partnership enabling freight forwarders to lease, buy and sell containers

| January 18, 2022 | Logistics | Shipping Technology

Former Uber exec joins fast-growing logistics startup Nuvocargo as Head of People

| January 18, 2022 | Shipping Technology

DispatchTrack accelerates global expansion with new UK headquarters

| January 18, 2022 | Shipping Technology

Axele TMS announces integration with Triumph Factoring and digital BOL upgrades

| January 18, 2022 | Shipping Technology

PenguinIN, Actility and Abeeway join forces to offer smart tracking solutions

| January 18, 2022 | Shipping Technology

PenguinIN, Actility and its subsidiary Abeeway are happy to announce a partnership aiming at expanding their IoT solutions portfolios with joint offers, focusing primarily on Managed Indoor Positioning and Navigation serving a wide range of industries including Healthcare, Construction, Oil & Gas, Airports, Education, Hotels, Theme Parks and Shopping Centers.

FourKites acquires European supply chain visibility leader NIC-place

| January 18, 2022 | Shipping Technology

Redwood delivers double-digit savings for RWI Logistics with RedwoodConnect

| January 18, 2022 | Logistics | Shipping Technology

RedwoodConnect™ integrates multiple supply chain technologies, eliminating costs, risks and months spent connecting systems manually

Fleetio adds Fleetyr as development services provider for third-party integrations

| January 18, 2022 | Shipping Technology

Fleetio, a leading fleet maintenance software, has selected Fleetyr as a preferred development services provider for third-party software integrations.

DDC FPO announces DDC Sync, a new intelligent enterprise application with in-cab mobile data capture

| January 18, 2022 | Shipping Technology

DDC Sync includes a native Android app with automated smart BOL capture and a robust web portal to help motor carriers harmonize their entire freight operation

Shippabo expands transloading services for customers with inland movement

| January 17, 2022 | Shipping Technology

Shoe companies are using Tecsys Technology to modernize retail fulfillment

| January 17, 2022 | Shipping Technology

Global footwear brands and retailers are leveraging Tecsys’ software platforms to unlock omnichannel distribution and fulfillment capabilities like inventory virtualization, dynamic routing and order consolidation.

ECS Group’s cargo digital factory and Wiremind Cargo join forces and launch CargoTech

| January 17, 2022 | Shipping Technology

New service from Gebrüder Weiss allows North American air and sea customers to offset their carbon footprint

| January 14, 2022 | Shipping Technology

By calculating emissions per shipment, the new service determines carbon footprint and provides an option to offset emissions via a certified climate protection project.

3Gtms releases updated version of TMS to help customers navigate capacity crunch

| January 14, 2022 | Shipping Technology

Version 21.3 includes new tools for freight brokers and 3PLs to grow their business with better tools to win more loads and efficiently secure carrier capacity

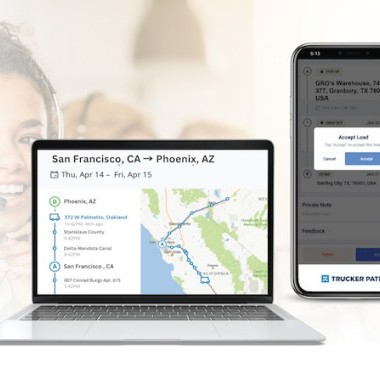

Trucker Path’s 1 million users now have access to Loadsmart

| January 13, 2022 | Intermodal | Shipping Technology | Trucking

Trucker Path, the most comprehensive and fastest growing mobile app for North American commercial truck drivers, today announced a partnership with Loadsmart, a leading digital freight technology company. The agreement between the companies integrates Loadsmart with Trucker Path’s TruckLoads digital freight exchange solution to streamline and offer a better booking experience for drivers and carriers.

© Copyright 1999–2024 American Journal of Transportation. All Rights Reserved